Revolutionary Barrel Cleaning Device: The Advanced ÇINGI for Military Applications

**In the wake of rapid advancements in modern weaponry and ammunition, the challenges surrounding barrel maintenance and cleaning are evolving as well. Traditional methods are often marred by logistical issues, including labor-intensive requirements and prolonged maintenance times. Recognizing these shortcomings, Defense Industry Technologies Inc. (SSTEK) has developed an innovative solution: the ÇINGI barrel cleaning device, tailored specifically for the T-155 FIRTINA Howitzers within the Turkish Armed Forces.**

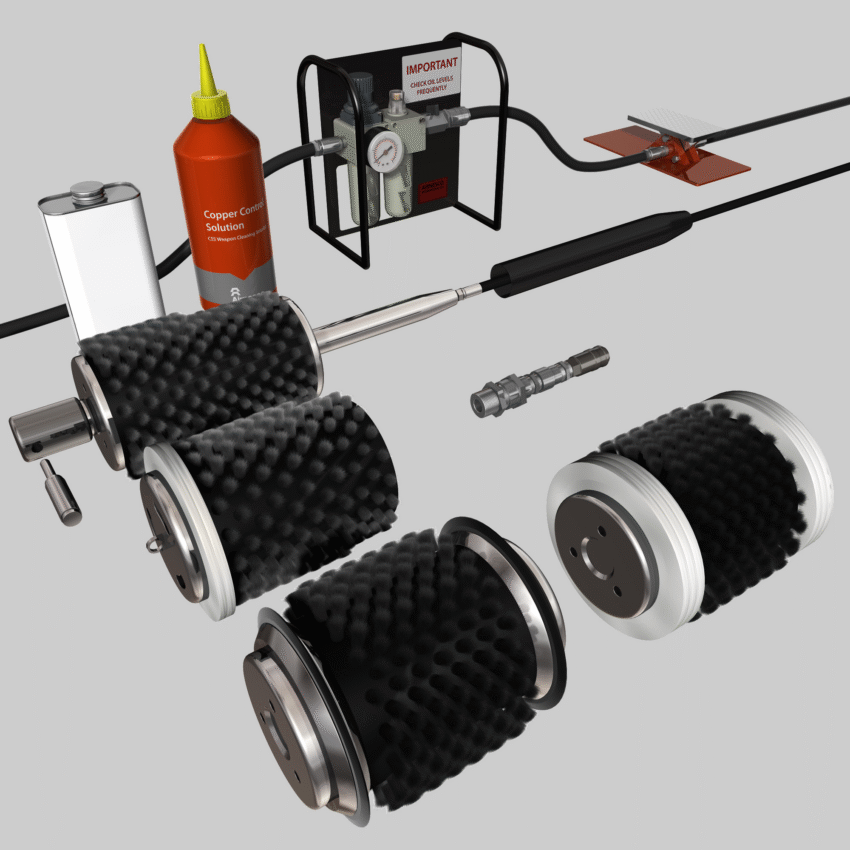

The ÇINGI is ingeniously engineered and comprises four key components: the Power Unit Section, Walking and Carrying Systems, Brush and Cleaning Unit, and Control Panel. Each section boasts distinct functional and technical specifications, ensured through rigorous analytical and practical studies.

Technical Specifications of the ÇINGI

The ÇINGI stands out with its impressive technical credentials. Measuring Ø 145 X 870 mm and weighing 21 kg, this device operates at a barrel progress speed of 1.8 to 2.2 meters per minute, with a total cleaning duration between 18 to 25 minutes. It is specifically designed for cleaning 155 mm barrels, featuring two brushes constructed from durable bronze and plastic, and operates effectively in a temperature range of -35 to +50 degrees Celsius.

Equipped with a cleaning fluid tank with a capacity of 900 ml and a powerful 24V drive, the ÇINGI can be directly powered by the vehicle’s electrical system. This functional design allows compatibility with various systems including the FIRTINA Howitzer, FIRTINA 2, G5, G6, Paladin, K9, and PZH 2000.

Benefits of the ÇINGI Barrel Cleaning Device

One of the standout features of the ÇINGI is its design, which minimizes the number of components for efficient assembly and disassembly by a single operator. Spare parts are readily available, adhering to market conditions, ensuring minimal downtime. It also provides a high degree of versatility, functioning across all 155 mm heavy weapon barrels regardless of specifications like rifling angles or brands.

Compared to foreign competitors that often require additional power sources or heavy equipment, the ÇINGI is lightweight and operationally portable, boasting a mobile control panel. This capability enhances user safety during combat situations by allowing operation from both inside and outside the vehicle.

Comparison with Foreign Barrel Cleaning Systems

A comparative analysis reveals that the ÇINGI not only weighs less than many foreign alternatives but also offers faster barrel cleaning progress rates. With a straightforward operation that does not necessitate an external power source, the ÇINGI showcases significant advantages over models like the RIFLEBORE BLD-155A, which demand higher weight and more complex operations.

Moreover, the maintenance process for the ÇINGI is user-friendly, in contrast to complex servicing requirements often associated with imported systems. This clarity in usability and efficiency has made it a preferred choice among its users in Turkish military applications.

Historical Development of the ÇINGI

The ÇINGI underwent significant development, beginning with initial concepts in November 2017, and achieving prototype manufacturing soon after. The first field test occurred in January 2018, yielding promising results that led to further evaluations by the Turkish Land Forces EDOK Command.

Subsequent assessments included rigorous testing phases at the 1st Main Maintenance Factory and continued user feedback aimed at fine-tuning the device. By September 2018, the ÇINGI was formally recognized for its effectiveness, marking a pivotal point in its adoption by military units.

User Feedback and Continuous Improvements

User trials conducted in various military settings highlighted the ÇINGI’s effectiveness in performing necessary barrel cleaning tasks, as reported by personnel during exercises. These hands-on evaluations led to enhancements in both design and functionality.

Feedback has emphasized the importance of maintaining a straightforward user interface, particularly stressing the need for manual operation capability to ensure operational continuity under adverse conditions.

Visual Evidence of Field Tests

The ÇINGI’s field test visuals captured during military exercises demonstrate its practical usage and operational readiness. These tests not only validated its design but also provided key insights into real-time performance.

With ongoing evaluations and updates based on user experiences, the ÇINGI is poised for greater integration into military operations, reinforcing its role as an essential tool for artillery maintenance.

Specifications for Related Models

Aside from the main model, the ÇINGI lineup includes additional variants designed for different barrel calibers. For instance, the ÇINGI 120 caters to 120 mm barrels with a progress speed of 2 to 2.4 m/min, while the ÇINGI 203 serves 203 mm barrels, showcasing the flexibility of this product line.

Each variant maintains similar high standards of reliability and versatility, ensuring they meet diverse military needs while operating effectively across varying conditions.

Final Thoughts on ÇINGI’s Impact

The ÇINGI barrel cleaning device symbolizes a significant leap forward in military logistics, merging technological innovation with practical functionality. Its domestically produced components underscore Turkey’s commitment to self-reliance in defense technologies.

Continued support and investment in such innovations not only bolster operational readiness but also enhance the overall efficiency of artillery units within the Turkish Armed Forces.